GLITTER PRINTING : plastisol inks and other consumables for glitter effects on textiles

Supports

Transfer media

Technical specifications

Printing :

Direct, transfer and sprinkling

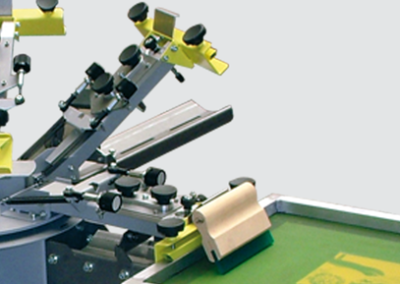

Equipment :

Manual, semi-automatic and automatic carousel

Washability :

Very good at 40°C

⚠ TIFLEX only provides the bases for printing glitter effects.

Composition :

Free of phthalates for elastic gloss bases, heavy metal salts, azo derivatives

Packaging :

5 Liters

Compliance :

ECO-PASSPORT by OEKO-TEX® certification for the HIMALAYA gloss base,

EN 71-3 standard, ROHS directive, REACH/CLP regulation

Contact us now on +33(0)4 74 37 33 83